Technology

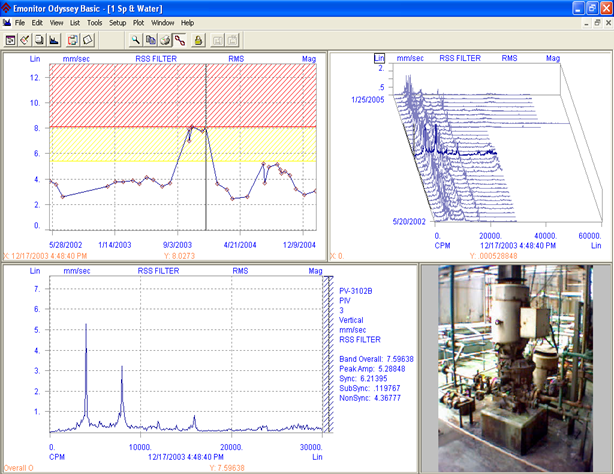

Vibration Monitoring and Implementation

A predictive technique of regularly monitoring selected parameters (typically vibration) of rotating equipment to identify early onset of machinery problems.

Benefits:

- Results in fewer unexpected failures

- Optimises resources and manpower

- Increased productivity

- Improved product quality

- Reduced maintenance costs

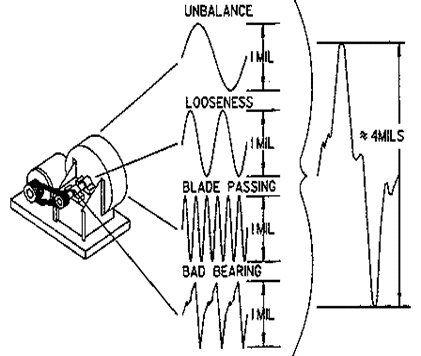

Machinery Diagnostics

In depth diagnostics of machinery problems due to resonance, misalignment, imbalance, looseness, bearing & gear faults, etc. It is applicable to most types of rotating machinery.

Benefits:

- Increase machine uptime and operational life

- Detect potential failures

- Reduce maintenance cost and hence increase plant efficiency

- Improve safety environment

Dynamic Balancing

On-site 1 or 2 Plane Dynamic Balancing can be performed for motors, fans, propellers, turbines and most other rotating machinery.

Benefits:

- No dismantling required hence time & labour cost minimize

- Increase machine life span and availability

- Prevent damage due to dismantling and transportation

- Improve safety environment

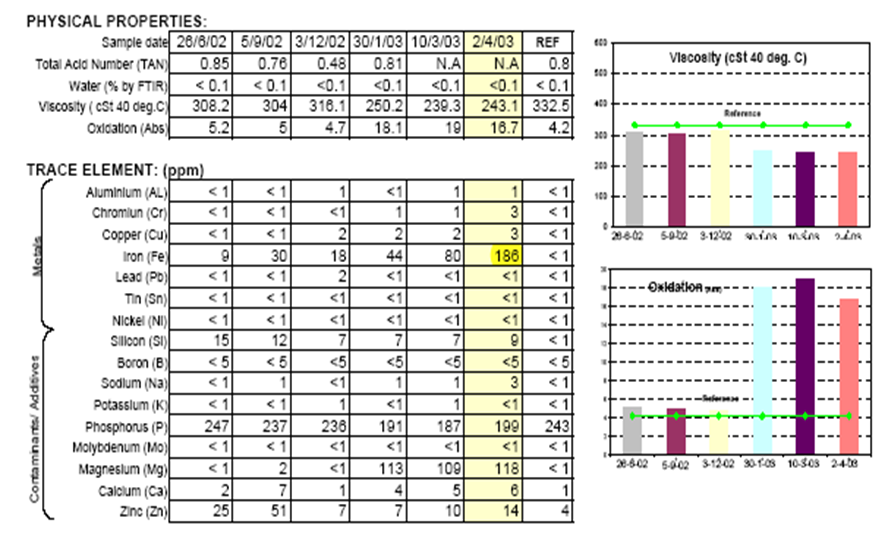

Oil Analysis

Assessment of oil degradation & contamination for the evaluation of machine being lubricated. Analysis testing performed locally or via a third party certified lubrication testing laboratory.

Benefits:

- Enables the proactive control that lead to lubricant & machine failure

- Identifies components which are at the onset of the severe wear stage

- Ideal as a complementary technique to vibration or infrared thermography

- Minimises the cost of laboratory analyses by scheduling on condition only, or less frequently for lubricant checks

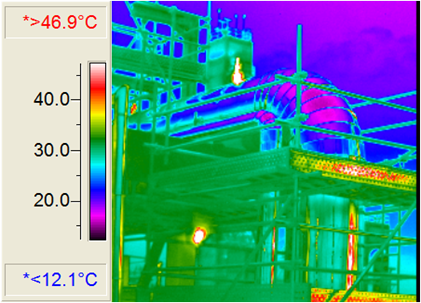

Infrared Thermography (IRT) Survey

Infrared Thermography can be used to identify any problem that is associated with a change in temperature that is out of the ordinary. IRT helps to pinpoint failures in electrical, mechanical & process related areas.

Benefits:

- Provides non-intrusive instantaneous inspection

- Detect potential failures & hazards

- Provides a complementary inspection method for the diagnosis of plant equipment, performance monitoring & safety evaluations